Why choose Brianza Plastica FRP laminates for cold rooms and cleanrooms?

Discover all the benefits of Elycold and Elyplan for environments requiring maximum hygiene, resistance, and durability.

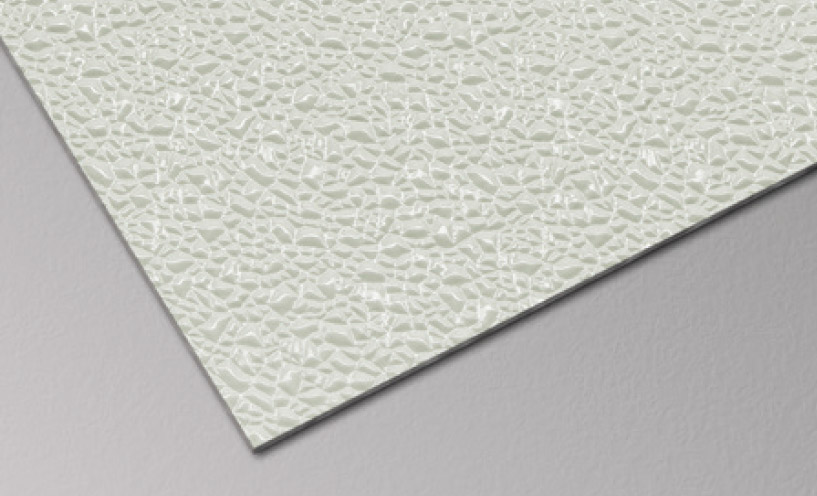

RESISTANCE

AND DURABILITY

Elycold and Elyplan laminates offer excellent resistance to corrosive agents, are completely waterproof, have low thermal expansion and ensure long-lasting performance.

HYGIENIC

SURFACES

Easy to clean and certified for food contact, Elycold and Elyplan do not release substances harmful to food products.

EASY

TO REPAIR

In case of accidental damage, fiberglass laminates can be easily repaired, maintaining their functionality and aesthetics unchanged.

HIGH IMPACT

RESISTANCE

Robust and resistant to impact and stress, ideal for environments exposed to heavy use and continuous movement.

SUITABILITY

FOR BONDING

Suitable for cladding surfaces to be renovated and for bonding to expanded polystyrene, extruded polystyrene and polyurethane substrates.

FOOD CONTACT

CERTIFICATION

EC-certified according to Regulation (EC) No. 1935/2004, for direct contact with food.

REFRIGERATED ENVIRONMENTS

COLD ROOMS

Brianza Plastica’s fiberglass laminates are EC-certified in accordance with Regulation (EC) No. 1935/2004, making them suitable for direct contact with food.

HYGIENIC ENVIRONMENTS

CLEANROOMS

Maximum cleanliness and hygiene are essential in cleanrooms for the pharmaceutical, medical and food & beverage industries. This requires the use of advanced materials that minimise the presence of bacteria on surfaces.

Elycold and Elyplan flat laminates by Brianza Plastica are the ideal solution for cladding walls and ceilings or adding an extra layer of protection. They are easy to clean, highly durable and resistant to corrosive agents.

This resistance also makes them an excellent choice for constructing structures in marine environments, where protection against salt-induced corrosion is critical.

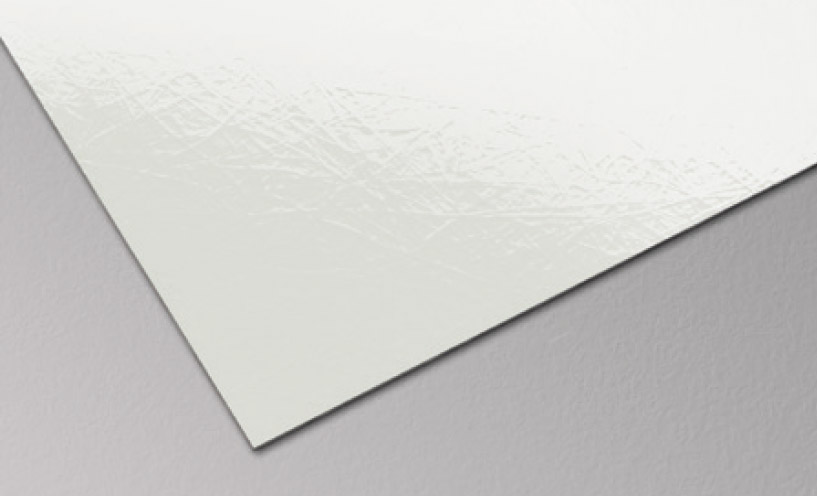

NO BAC

ANTIBACTERIAL

PROTECTION

The NO BAC technology developed by Brianza Plastica is specifically designed for environments requiring a high level of hygiene. It reduces the presence of bacteria on the surface of the GRP laminate, preventing subsequent colonisation and thus ensuring a high level of added protection in any environment.

The silver-based NO BAC technology is permanently integrated into the laminate during the production process. Evenly distributed across its entire surface, it provides antibacterial protection throughout the product’s life cycle. The NO BAC technology is available on Elycold and Elyplan GRP laminates with an external gelcoat finish.

Applications

FOOD

CLINICAL / HOSPITAL

CATERING

ELECTRONIC

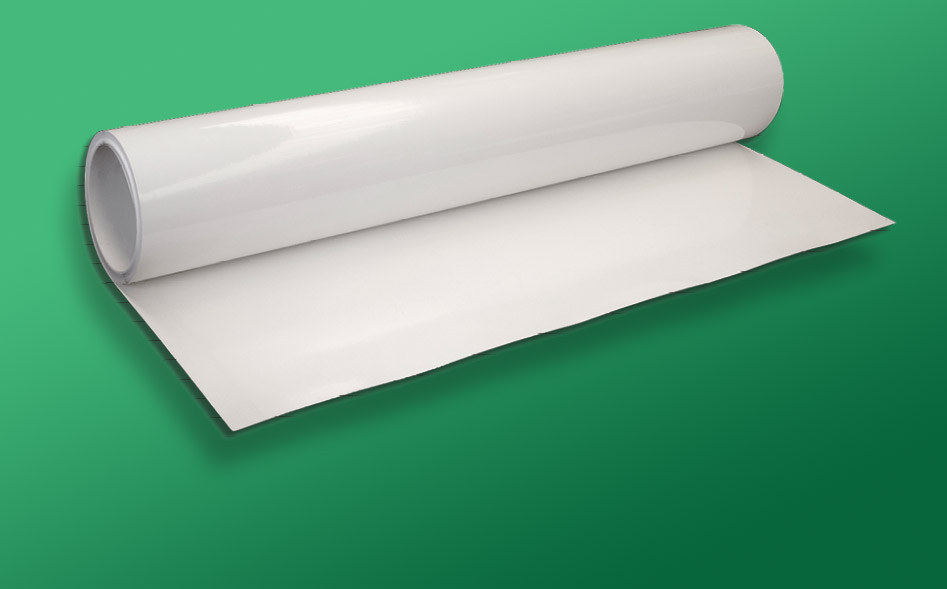

ELYCOLD GRP LAMINATES

Rolls and sheets produced by

discontinuous lamination

Elycold is a combination of polyester resins and glass fiber; over the years, this composite material has replaced aluminium in the production of panels for refrigerated and commercial vehicles, campers, caravans and motorhomes, proving to be the optimal solution also for applications in cold rooms, cleanrooms, and mobile homes.

PRODUCT DIMENSIONS (ROLLS / SHEETS)

- Thickness: from 1 to 3.6 mm

- Width: up to 3,400 mm

- Length: 60 m

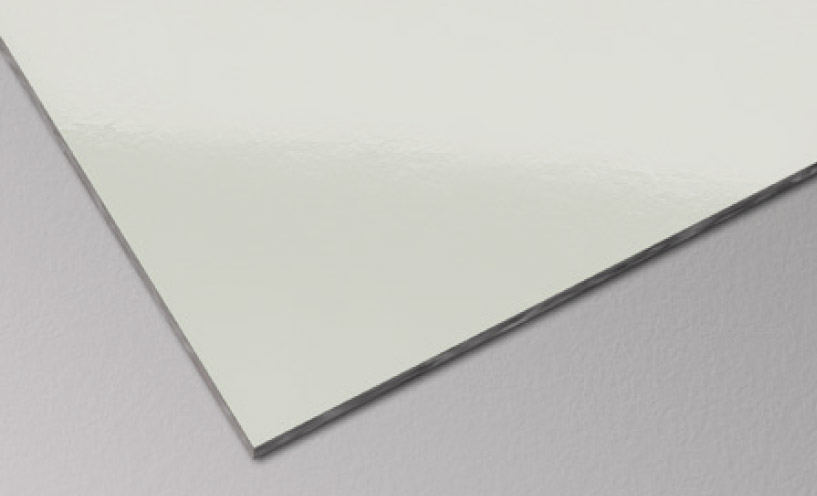

ELYPLAN GRP LAMINATES

continuous lamination

ELYPLAN is manufactured in continuous on cutting-edge machinery, thanks to over sixty years of experience in the fiberglass laminates sector.

Ideal for application in temperature-controlled and recreational vehicles, cold rooms, and cleanrooms, it offers smooth, highly resistant, and easily washable surfaces. Continuous hot production ensures perfect flatness at competitive prices.

PRODUCT DIMENSIONS (ROLLS / SHEETS)

- Thickness: from 0.8 to 3 mm

- Width: up to 3,200 mm

- Length: on request

Brianza Plastica Group

The Brianza Plastica Group is made up of three companies that contribute to the study, production and supply of high-quality materials and products, thus making the Group a leader in the field of fiberglass laminates and industrial and civil insulation. All Brianza Plastica products are made in Italy in the company’s five production plants.

Fiberglass sheets and rolls are produced in four production facilities entirely dedicated to these products: Carate Brianza, Ostellato, and two in San Martino di Venezze.

The companies making up the Brianza Plastica Group are:

- Brianza Plastica S.p.A.

- Plasti-Bat S.a.s.

- Brianza USA Corporation